Capabilities

All sizes up to 4” diameter are of our typical manufacture.

Larger sizes may be available upon customer request.

These parts can be made to fit any design and size allowed for in MSS-SP-79. Additional sizes can be manufactured to customer design specification.

Material

Parts can be manufactured out of material conforming to ASTM specifications A234 WPB, A403, A420 or any of their ASME equivalents.

Piping components can be made to customer material specifications and out of most brass and carbon, stainless, or alloy steels as required.

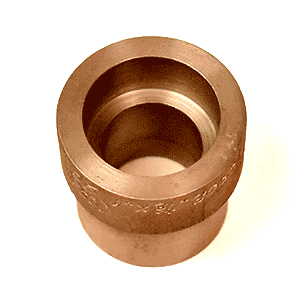

Reducing Inserts

This Standard Practice covers ratings, dimensions, tolerances, finish, marking and material requirements for socket-welding reducer inserts for use with ASME B16.11, Class 3000 and 6000 socket-welding fittings.

Fittings with special dimensions and fittings made from non-standard materials may be designed and manufactured by agreement between the manufacturer and the purchaser, provided they are marked in accordance with the requirements for partial compliance fittings of Section 5.1.1(e).

Welding – Installation welding requirements are not within the scope of this Standard Practice, except for:

(1) The CAUTIONARY NOTE REGARDING INSTALLATION OF SOCKET-WELDED JOINTS (see Section 12)

(2) The WELDING GAP AND MINIMUM SOCKET WALL THICKNESS (see Figure 1)

(3) The GAP RECOMMENDATIONS (see Figure 2). Installation welding shall be done in accordance with the applicable piping system into which the fittings are to be installed.

[sp_testimonial id=”308″]